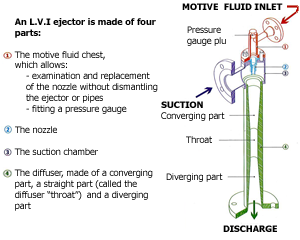

Ejector principle

The ejectors are static devices in which the energy provided by the release of pressurized fluid (steam, gas, liquid ....) can:- Aspire, compress or mix fluids

- Put vacuum or pressurized enclosures

- Transfer fluids, powders or sludge

- Transfer of heat

Benefits

- CUSTOM DESIGN AND MANUFACTURING: Thank to our resources which have been validated by thousands of achievements, we provide well sized ejectors for each specific application, ensuring optimum performance (and security) at competitive prices

- HIGH PERFORMANCE: The specific profiles of our ejectors guarantee maximum efficiency for a reduced operating cost.

- EXCEPTIONAL RELIABILITY: due to the lack of moving parts, no breakdowns, no decrease in performance, a low maintenance cost.

- WIDE RANGE OF RATES: An unlimited suction capacity (our most important achievement: 1 400 000 m3/h).

- WIDE RANGE OF PRESSURE: Our ejectors can also be used to make a vacuum within a chamber (up to 10 -2 mbar abs.) or use as compressors for several dozens of bars.

- CORROSION RESISTANCE: Ability to aspirate any fluids, even abrasive or corrosive thanks to the diversity of building materials that we offer.

- ABILITY TO USE THE GAS METHOD AS WORKING FLUID, which remove significant pollutions

Our ejector manufacturing is defined by our customers' needs:

- Materials: All materials can be used. Among the most common steel, carbon, stainless steels (304L, 316L ...), Special Alloys (Uranus, Monel, Hastelloy ...), graphite, plastics (PVC, PPH, PVDF, PTFE ...)

- Codes and design guidelines: LVI's standard, CODETI, CODAP, ASME VIII, AD-MERKBLATTER, Normes CE, TEMA, DESP...

- Connection: On demand, flanges (as ISO, DIN or ANSI), threaded connections, threaded or welded.

Examples of application