Vacuum group principle

A vacuum group is composed of ejectors mounted in series (and / or in parallel) for obtaining a suction capacity and a vacuum level as specified by our customers. A vacuum group relies on working fluids, cooling fluids and available energy sources. Depending on the suction pressure applied and the cooling temperature, a vacuum group can have up to 6 compression levels. It may be associated with several technologies such as liquid ring pumps. Some examples are given below:Multi level Vacuum groups

With mixing condensers

Vacuum group with 3 levels and 2 intermediate condensers as well as a final condenser for a fertilizer plant.

With tubular condensers

Vacuum group with 2 levels of stacked intermediate and final condensers in refinery for diesel drying unit.

Vacuum group with 2 levels of intermediate and final condensers in line, for starting up a turbine condenser.

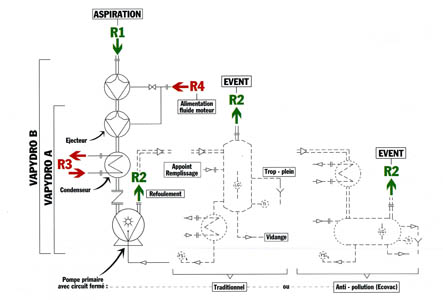

Mixed Multi level Vacuum groups (VAPYDRO)

Description

The VAPYDRO is composed of one (A serie) or two (B serie) steam ejector(s), a condenser and a liquid ring pump. The output gases are first

compressed in ejector(s), then the working steam is condensed in an exchanger tube.

is composed of one (A serie) or two (B serie) steam ejector(s), a condenser and a liquid ring pump. The output gases are first

compressed in ejector(s), then the working steam is condensed in an exchanger tube.

The output gases of the exchanger and condensates are finally sucked into a primary pump and repulsed in the atmosphere (See block diagram below).

Benefits

- Low price and operating cost

- Exceptional reliability (The ejectors are statics)

- Easy to maintain

- Limited noise

- Delivered as turnkey

- Corrosion resistance

- Aspirate steams or dust loaded gases

Options(dotted line on block diagram)

- Removable bundle heat exchanger (U form)- Check valve between condenser and pump

- Downstream gas / liquid separator of the liquid ring pump

- Measurement and security instrumentation

- Explosion-proof engine (EExd II BT 4)

- Separator kit on powered working steam

- Regulator of working steam

Examples of realizations