Hydroejector principle

These ejectors works with a liquid fluid (mainly water). They are able to provide a vacuum level close to steam pressure of fluid (without cavitations) and / or very high anti-pressures. These equipments can also be used to create vacuum or compression. In addition, they combine the condensation and gas scrubber functions.

As a consequence, we have developed "universal" vacuum groups around this technology. These groups can operate in anti-pollution ATEX zone as POLYVAC H series or corrosion / anti-pollution zone as POLYVAC V series. Combined with steam ejectors fitted in series, they lead down low level vacuum (1mbar abs) and aspire significant flows.

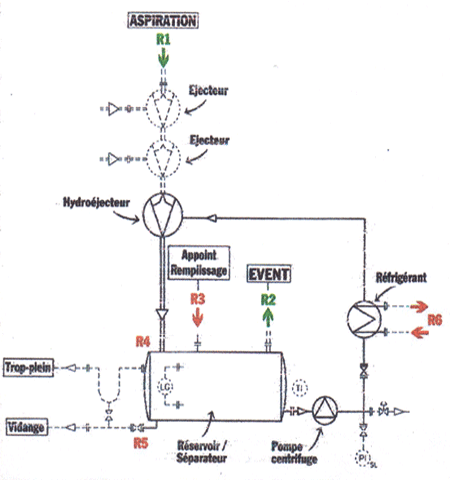

POLYVAC H series

Description

A high performance liquid jet ejector aspires noncondensable gases and condenses and / or neutralizes and / or absorbs steams which are collected in the separator tank with the working liquid. A centrifugal pump recycles the fluid while saturated noncondensable are evacuated via the vent.The recycled temperature content remains constant by an external heat exchanger in the tank.

The waste steam quantities, released to the vent, no more depend from the coolant temperature of the heat exchanger and the working fluid (according to its absorbency and / or neutralizing power).

Benefits

- Ability to aspirate loaded gas (with dust ...) and / or high temperatures liquids

- Toxic or malodorous gaz scrubber by use of an appropriate working fluid

- Ability of operating with working liquid of the same nature of the aspirated fluid

- Recovery of condensed steam in the tank and discharge pressure without extraction pump

- Exceptional reliability (equipments are static)

- Compact group and delivered ready to connect

Options (dotted line on the block diagram)

- Steam ejector (or ROOTS depression type) on the aspiration to achieve a higher vacuum and flow rates- Air ejector on aspiration to achieve a higher vacuum (30 to 3 mbar abs.) at a reduced rates (de 2 Ó 100 m3/h)

- Suction check valve

- Measurement and Security instrumentation

- Automatic valve for evacuating condensates

- Centrifugal pump with magnetic drive

- Bundle exchanger tube (type BEM) or removable plates

Examples of Realization

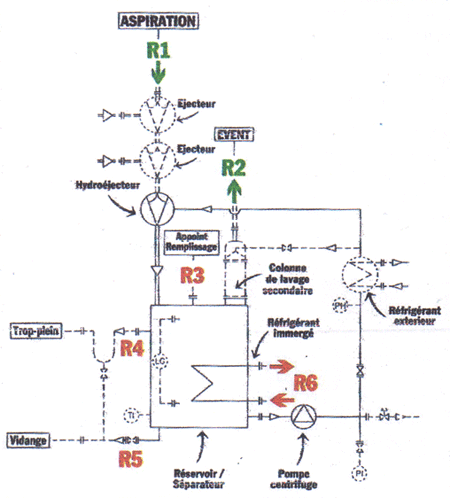

POLYVAC V series

Description

A high performance liquid jet ejector aspires noncondensable gases and condenses and / or neutralizes and / or absorbs steams which are collected in the separator tank with the working liquid. A centrifugal pump recycles the fluid while saturated noncondensable are evacuated via the vent.The recycled temperature content remains constant by an immerged heat exchanger in the tank.

The waste steam quantities, released to the vent, only depend on the coolant temperature of the heat exchanger and the working fluid.

Benefits

- Ability to aspirate corrosive gases and / or loaded (with dust ...) and / or liquids

- Toxic or malodorous gaz scrubber by use of an appropriate working fluid

- Ability of operating with working liquid of the same nature of the aspirated fluid

- Recovery of condensed steam in the tank and discharge pressure without extraction pump

- Exceptional reliability (equipments are static)

- Compact group and delivered ready to connect

Options (dotted line on the block diagram)

- Steam ejector on the aspiration to achieve a higher vacuum (de 30 Ó 0,5 mbar abs.) and flow rates- Air ejector on aspiration to achieve a higher vacuum (30 to 3 mbar abs.) at a reduced rates (de 2 Ó 100 m3/h)

- Suction check valve

- Secondary gas scrubber on the vent

- Hydraulic seal device

- Measurement and Security instrumentation

- Automatic valve for evacuating condensates

- External centrifugal pump

- External exchanger

Examples of Realization